Container, 1 column

1 column

1/2 column

1/2 column

1/3 column

1/3 column

1/3 column

1/3 column

2/3 column

1/4 column

1/4 column

1/4 column

1/4 column

1/4 column

3/4 column

1/5 column

1/5 column

1/5 column

1/5 column

1/5 column

1/5 column

4/5 column

1/6 column

1/6 column

1/6 column

1/6 column

1/6 column

1/6 column

1/6 column

5/6 column

Virtual Interview with Author Corban Addison

Last month, Sustainable Westport and the Westport Library hosted a virtual interview with author Corban Addison to discuss his new nonfiction book, “Wastelands: The True Story of Farm Country on Trial.” In the vivid and fast-paced thriller, Mr. Addison shares the story of North Carolina residents who stood up to a multi-billion dollar international corporation for polluting their community.

Sustainable Wesport Co-Director, Johanna Martell, mediated the conversation with Mr. Addison. She reflected on the conversation “Wastelands is an incredible story and a great example of environmental justice at work. It is representative of what happens on the global stage where often the polluters are the wealthy and powerful 1% and the disenfranchised and less powerful are ones left dealing with the ramifications.”

In the words of Mr. Addison, “And that’s the simple question: will Smithfield be willing to spend some of its billions in order to civilize its business model for the benefit of its neighbors and for the benefit of mother nature and the environment.”

You can view the full interview here.

How to Make Your Yard More Sustainable

It’s time to shift our thinking about lawn care. In America, we consider a lush, green turf lawn the ultimate socio-economic status symbol. A perfectly manicured grass-only lawn does not come naturally and grass is not meant to grow in isolation. Not only do lawns require a substantial amount of time and energy, they are expensive and require chemicals that have negative impacts on our environment.

40% of Westport properties contain wetlands, so the use of fertilizers and pesticides often end up downstream in the Long Island Sound impacting water quality and all levels of the ecosystem. In addition to polluting our waterways, lawn chemicals also poison us and our pets. The Guardian recently reported that more than 80% of urine samples drawn from children and adults in a US health study contained a weed killing chemical, glyphosate, which has been linked to cancer. This is the active ingredient in herbicides sold around the world, including the widely used Roundup brand.

Lush lawns require massive amounts of water (watering the lawn generally accounts for 50 percent to 75 percent of a home’s water use during the summer). The lack of diversity in a picture-perfect lawn downgrades our watershed and does not nurture the ecosystems needed to support wildlife like bees, butterflies, birds, and other insects. A biodiverse lawn, full of clover and other “weeds,” improves our soil quality, provides pollen to support wildlife, and results in a more resilient, reparative, and low maintenance yard.

So what do you do? Unfortunately, we can’t just stop mowing. That would only yield a mess.

SIMPLE STEPS

- Raise the mower blade to a cutting height of three and a half or four inches

- Decrease watering and skip the chemicals and pesticides

- Top-dress your lawn in a half inch of compost to increase the biological activity in the soil, to support the grass naturally

- Reduce the total square footage of your lawn and replace it with something else entirely like a native planting meadow or stone patio

MAKE A RADICAL SHIFT

Many lawn alternatives are low-maintenance and naturally attract birds, bees, butterflies, and other beneficial insects. An “eco-lawn” or “low-mow” grass blends grow in spring and fall, and once established, only require mowing once or twice a year. Another alternative: clover, which can adapt to semi-shade and provides some pollinator benefits, because it flowers.

It’s time to turn our lawns into productive plant communities! Learn more about maintaining a healthy and sustainable lawn on our website here.

Sustainable Westport Superstar: Dr. Rebekah Browder & Westport Family Dental

Westport Sustainable Superstar:

Dr. Rebekah Browder reached out to Sustainable Westport seeking advice on how she could expand her sustainability measures at her local dental practice, Westport Family Dental. However, what we learned is that she is already way ahead of the curve and already making every effort possible to identify and make changes in a business that is rife with (unavoidable) waste.

In an industry with so much plastic and single-use waste, how have you made changes in the office?

“The healthcare field certainly isn’t set up to be eco-friendly but we were able to make several meaningful improvements. We use sterilizable and reusable dental products as much as possible, source sustainable office products, and we partner with Terracycle to prevent oral health products from going into the waste system. Patients and non-patients alike are free to drop off their used toothbrushes, toothpastes, floss, and mouthwash bottles, as well as clear aligners, like Invisalign, to be recycled by Terracycle into usable materials.”

Why was B-corp certification important to you? (her practice is one of only a few B-Corp dental practices in the US)

“B-corp certification became important to us quite quickly. At the very least, it would be a great exercise as a new business owner to evaluate my practice and ensure I was running a company that would make me proud. I was fortunate enough to partner with Kerrie McDevitt and Impact Growth Partners to guide me through the process. What I found was that if we really wanted to attain B-corp certification, we couldn’t get by with just being nice people. We needed to walk the walk and put our money where our mouths are. We were able to re-evaluate everything from our community involvement, charitable practices, and environmental impact, to the satisfaction of our patients and team members. The more I learned, the more passionate I became about creating a practice that was truly different, a dental practice that was a force for good inside the mouth and out.”

What can people do at home in their dental routine to be more environmental or sustainable?

“There are many options. If you keep your current routine, simply recycle your products. The next step would be to use reusable, rechargeable electric toothbrushes and Waterpiks. And if you really want to take things up a level, you can switch to bamboo toothbrushes, a stainless steel tongue scraper, biodegradable silk floss in glass containers, and toothpaste tablets to create a zero-waste oral healthcare routine.”

Rebekah’s contribution extends beyond her direct efforts. She also contributes at least 2% of her annual revenue to a variety of charitable partners. To learn more, visit https://www.westportfamilydental.com/. Let’s support businesses that support our planet!

Where does all our trash go?

In the past few months, we’ve heard a lot of misinformation, and questions, and frustration around waste and recycling so let’s talk TRASH! To start, we’ll share a brief overview of regional “trash-landscape” and in future blogs, we’ll dive into local processes and overall recycling.

Have you ever wondered, as you observed the smoke billowing out of the striped stacks on the drive through Bridgeport on the south side of I-95, “What are they burning over there”? It’s our trash! What you are looking at is Wheelabrator Bridgeport, a waste-to-energy facility that is the recipient of all of Westport’s “post-recycled trash” (more on that term in months to come).

In the mid 1980s, as landfills around Connecticut began to exceed their capacity, the State of Connecticut started an initiative to close the landfills and divert the waste to newly built or converted incinerator facilities. These “waste- to- energy” plants use the same basic process as fossil fuel plants with one critical difference: instead of burning oil or coal they burn your trash! The heat produced from combustion creates steam that is pushed through a turbine to turn a generator and produce electricity. Recent technology improvements have reduced air pollutants, making incinerator facilities substantially cleaner than their predecessors.

There are currently five operating waste to energy plants in Connecticut, the largest of which is in Hartford (“MIRA”). This plant is publicly owned and operated, and accounts for processing 35% of the state’s waste. In Southwestern CT, the waste to energy plant known as “Wheelabrator” processes about 28% of the states waste and is privately owned and operated by WINWASTE INNOVATIONS, a partnership of Wheelabrator, Tunnel Hill Partners (an integrated waste to rail company), and City Carting. Both of these plants have been in operation since 1989. Critically, MIRA is slated to close permanently THIS summer after facing significant economic challenges including the need for capital improvements as well as increasing operations and management costs. This impending closure will force the remaining four plants to absorb the burden of additional waste or it will be shipped out of state, neither of which is an ideal solution.

Advantages of the waste to energy process are that it reduces the total volume of “post-recycled” waste by approximately 90% (the majority of what remains for landfill is ash). Alternately, waste would be shipped by truck out of Connecticut to locations in Ohio, upstate New York, and Pennsylvania at significant cost to taxpayers, with increased use of fossil fuels and production of CO2. The sorting process at these plants also removes and recycles tons of metal each year that would otherwise be buried in landfill. At Wheelebrator alone, enough electricity is produced annually to power approximately 60,000 homes (57MW) which is the equivalent of 968,567 barrels of oil or 291,491 tons of coal saved in “clean energy”.

Opponents of burn to energy plants cite that significant amounts of CO2 are still produced (waste incinerators are amongst the top greenhouse gas emitters in Connecticut), and more importantly, the plants are frequently associated with high levels of air pollution and increased incidence of pulmonary illnesses amongst neighbors. Furthermore, 3 of the 5 waste incinerators in the state are located in environmental justice communities – neighborhoods that are disproportionately burdened by multiple sources of pollution and socio-economic vulnerabilities. Other arguments against waste-to-energy facilities cite concerns that burn plants may de-incentivize recycling in general, but particularly in the destruction of valuable materials including minerals, woods, and plastics. Finally, it is important to remember that burn plants still create ash and that product itself has to be landfilled (most of the ash produced in Connecticut is discharged in the Town of Putnam, CT).

Connecticut produces 2.4 million tons of waste per year, an average of 1600 pounds per person per year (consistent with the national average). Of that total, waste to energy facilities in Connecticut process 1.4 million tons of our solid waste. The rest (almost 1 million tons) is shipped out of state for deposit in landfill. With the impending closure of the MIRA plant in Hartford and subsequent strain that will place on Wheelebrator, and continually increasing waste due to lack of composting and proper recycling, Connecticut finds itself in a “waste crisis.”

So what can you do?? REDUCE, REUSE, RECYCLE and DIVERT FOOD WASTE/ROT.

Remember learning that adage in school? It really can be that simple! Be thoughtful in your purchasing and favor reusable over disposable (even if it requires a bit more money or personal energy). Repair broken items instead of tossing them away. And the great news is that Westport has a number of programs currently in place to assist and support your efforts to reduce overall waste:

- Separate your glass from other recycling and deposit at the transfer station

- Redeem your cans and bottles at participating facilities

- Join the Zero Food Waste Challenge

- Learn about all the other items that can be individually recycled and where!

Rev. Dr. Jim Antal Visits Westport to Talk Costal Communities

Sustainable Westport was proud to partner with Wakeman Town Farm and Saugatuck Congregational Church to welcome climate activist, author, and speaker, the Rev. Dr. Jim Antal to Westport. Dr. Antal’s presentation, entitled “Let’s Make Our Costal Community a Climate Leader,” discussed climate crisis realities and solutions, considering both global, local, and regional responses that impact our community. Afterwards, Sustainable Westport and Wakeman Town Farm presented overviews of our organizations and discussed local responses to the climate crisis. Watch the full discussion below!

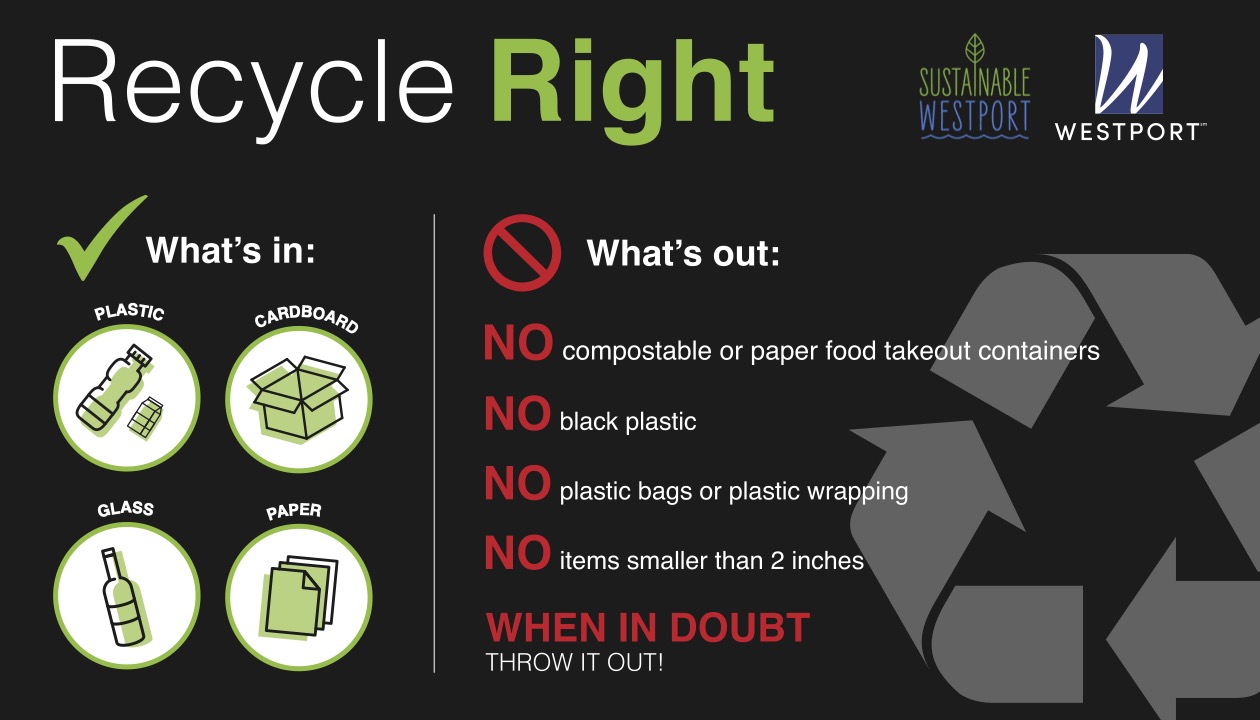

New Recycling Signage in Westport

Collaborating with the town of Westport, Sustainable Westport developed new informational signage for our town recycling bins. Wondering why it’s so important to “keep the stream clean”? Adding items that cannot be recycled can contaminate the entire bin, meaning most of it will end up in the incinerator. Next time you are in town check them out and do your part to help keep our stream clean!

Sustainable Westport Receives Westport Rotary Grant

Thank you to the Westport Rotary Club for selecting Sustainable Westport as a recipient of one of the 2022 Community Partnership Organization grants. The grant was hand delivered to Sustainable Westport’s Co-Directors Gately Ross and Johanna Martell by Westport Rotary Club representative, Dede McDowell.“It was an honor to be recognized alongside so many other mission-driven organizations in the greater Westport area. We plan to use our grant to sponsor a town-wide student art contest to increase awareness and educate residents on the value of recycling glass independent of the general recycling stream ”

– Gately Ross, Co-Director of Sustainable Westport

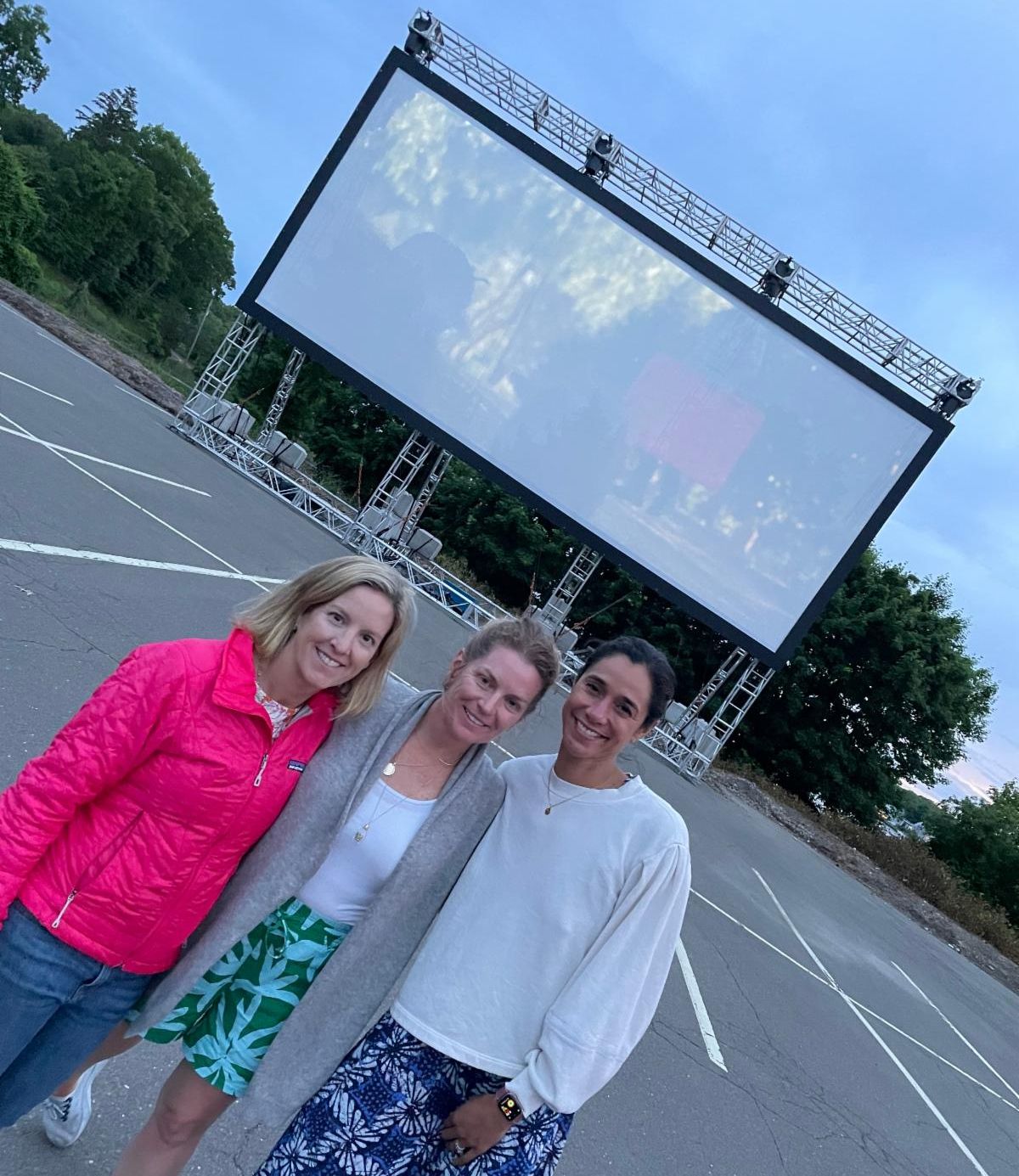

Screening: The Biggest Little Farm

Pictured: Lori Cochran-Dougal, Director of the Westport Farmers Market, along with Sustainable Westport Co-Directors, Gately Ross and Johanna Martell

In May, Sustainable Westport, along with Westport Farmers Market hosted a screening of “The Biggest Little Farm,” at Westport’s Remarkable Theater. The film chronicles the eight-year quest of John and Molly Chester as they trade city living for 200 acres of barren farmland and a dream to harvest in harmony with nature. We’ll be hosting more films this year – be on the lookout for dates!

Sharing Composting Tips with Westport Moms

More food is incinerated than any other single material in our everyday trash, constituting 22% of discarded municipal solid waste. In addition to being mindful about what you buy at the store, composting is one of the most impactful ways to reduce your family’s overall waste. Recently, Sustainable Westport partnered with Westport Moms, a local community-based resource for parents in Westport, to share our composting starter tips and to introduce the Westport Zero Food Waste Challenge. Our goal is to reduce town-wide residential food waste by at least 25%.

Check out the video and tips below to kick-start your composting journey and keep us posted on your progress by using the #westportzfw hashtag on Instagram.

HOW TO GET STARTED WITH COMPOSTING

- Get a starter kit from a commercial hauler or buy (1) a countertop container that works for you; (2) a 5 gallon bucket to keep in your garage or other cool area and (3) a set of BPI certified compostable liner bags for the countertop container and 5 gallon bucket.

- Pick a location for food scrap collecting that works for your household – a prep sink, in a garbage, or recycling pull-out or on the counter.

- Sign up for a commercial hauler (www.curbcompost.org) or (www.actionwastesolutions.com) to pick up your food scraps once a week. Mention Sustainable Westport in the comments and get one free month of service. OR bring your bagged food scraps to the Transfer Station (free of charge) at whatever frequency works for you.

- Educate your household so that you can begin to form good habits. Don’t know exactly what goes in or not, check with your hauler or on our website.

- Follow @sustainablewestport on instagram, post pictures of you and your family composting and tag us and #westportzfw

- Visit www.sustainablewestport.org if you have more questions and always feel free to email us at info@sustainablewestport.org.

Give yourself some grace! Mistakes will happen but keep trying!

Where do Those Food Scraps Go?

Now that you’ve joined the Zero Food Waste Challenge and started diverting food waste from the incinerator, the question arises: where do those scraps go and how exactly are they broken down into compost? Whether you drop your scraps at the transfer station or have them picked up by a commercial hauler, all of Westport’s food waste is transported to one of two sites in Connecticut. Surprisingly, the two sites process the waste in completely different methods: either via aerobic (with oxygen) or anaerobic (without oxygen) breakdown and yield completely different end products! To learn more about one of these sites, Curbside Compost graciously invited Sustainable Westport to join a tour of New Milford Farms.

New Milford Farms, 35 miles north of Westport in New Milford, Connecticut, was the first permitted composting site in the state. The open covered facility is enormous with rows and rows of large piles of decomposing food waste mixed with wood chips in specific ratios to create the ideal carbon:nitrogen balance. The piles are intermittently turned over mechanically to promote oxygen penetration, necessary to support the naturally occurring microorganisms that breakdown the organic material. This is an aerobic process (in the presence of oxygen). Over the course of 12-16 weeks depending on temperature and moisture levels, the materials decompose and become increasingly refined. Heat is created by the breakdown of materials and can be seen rising off the piles as water sprays over other piles to help maintain adequate moisture levels. The last step in the process is sifting through a ⅜” screener to remove any remaining contaminants, with one exception that sneaks through the screen – PRODUCE STICKERS!! Compost from New Milford Farms is then packaged and sold to retail garden centers.

The second endpoint for Westport’s food scraps is Quantum Biopower in Southington, CT. In contrast, this facility employs an anaerobic process, and produces clean energy in the process! To learn more about Quantum Biopower and more specific details on anaerobic composting, click here.

Regardless of your food scraps’ final destination, composting is a fantastic way to decrease your community-produced greenhouse gas emissions while producing valuable end products. If you have not started yet, now is the time to join us! Learn all about composting and your various options here in Westport.